Click above for larger image

Click above for larger image

Corporate Office:

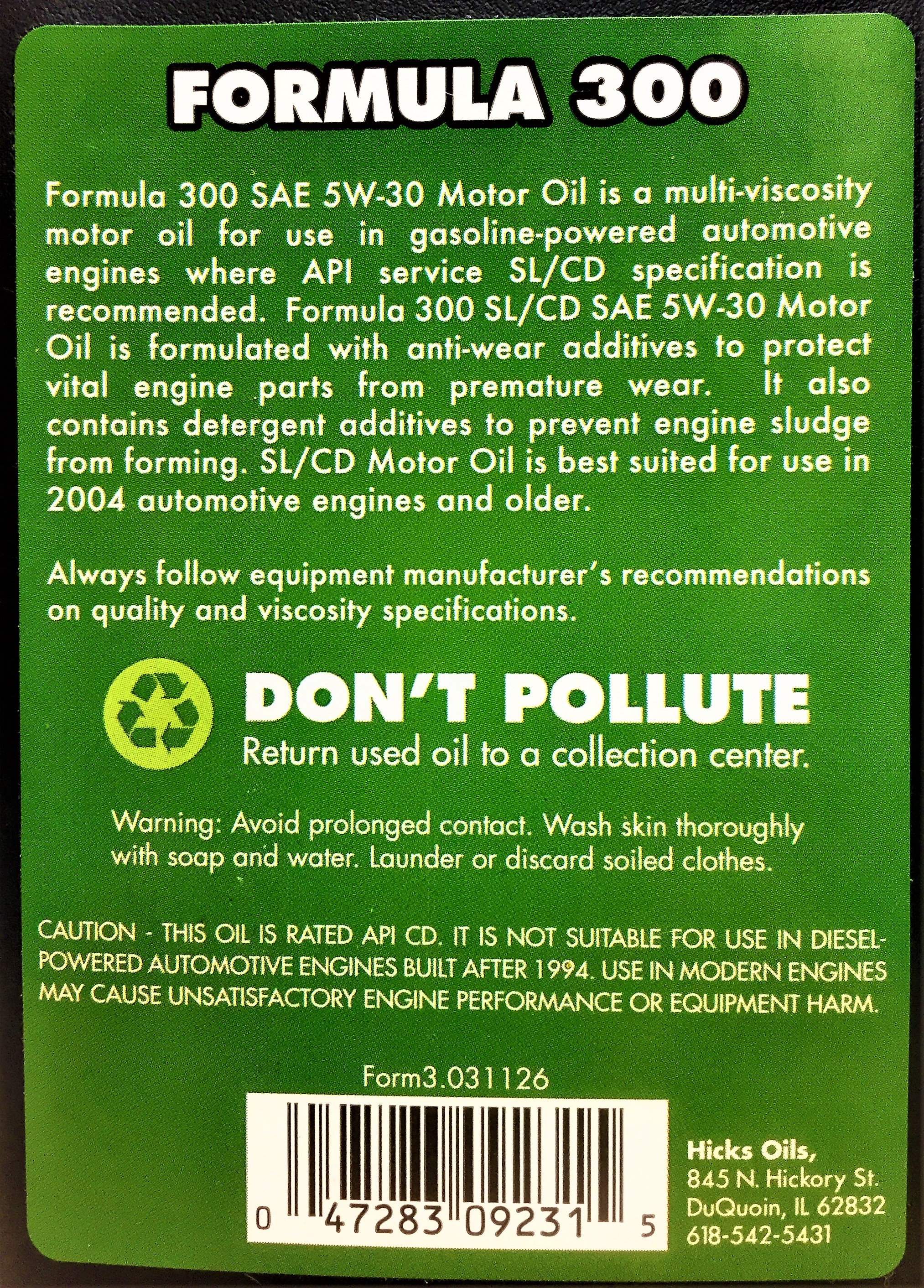

Hicks Oils

845 N. Hickory St.

DuQuoin, IL 62832

Website(s): www.hicksoils.com

Hicks Oils blends and packages motor oil, hydraulic fluid, gear lubes, transmission fluids and various specialty lubricants to fulfill most industries' lubricant needs.

Source: Hicks Oils Website

Manufactured by: Hicks Oils, DuQuoin, IL

Purchased at: Cleveland, OH

Date of purchase: 9/15/2017

Website(s): www.hicksoils.com

The results of the tests conducted on this sample meet the SAE J300 specifications for the SAE Viscosity Grade listed on the product label, and are consistent with the listed API Service Category.

Note: Whereas the label on this product states "Multi-Viscosity Formulation API SL/CD," it does not display the API Donut certifying that it meets the performance requirements set by the API and subject to quality testing conducted by the API's Aftermarket Audit Program (AMAP). Although the results of the tests conducted on this sample are consistent with the API SL Service Category, this does not assure full compliance.

As noted on the back label of this product, "SL/CD Motor Oil is best suited for use in 2004 automotive engines and older." And "CAUTION - THIS OIL IS RATED API CD. IT IS NOT SUITABLE FOR USE IN DIESEL-POWERED AUTOMOTIVE ENGINES BUILT AFTER 1994. USE IN MODERN ENGINES MAY CAUSE UNSATISFACTORY ENGINE PERFORMANCE OR EQUIPMENT HARM."

|

Physical Properties |  |

||||||||

| Elemental Analysis |  |

|||||||||

| Labeling |  |

|||||||||

|

||||||||||

Note1: Although laboratory tests alone cannot be used to establish if engine oil meets an API Service Category, they can be used to determine if it doesn't. Note2: The specification for cold cranking viscosity includes only a maximum value; the minimum value shown in the “standard” area of the chart is truncated for illustrative purposes. Note3: The specification for phosphorus includes only a maximum value; the minimum value shown in the “standard” area of the chart is truncated for illustrative purposes.

| PHYSICAL TESTS (click for test details) - a | Standard | Formula 300 |

| TBN, mg KOH/g (ASTM D2896) | 6.11 | |

| Viscosity @ 100ºC, cSt (ASTM D445) | 9.3 to <12.5 | 10.07 |

| Viscosity @40ºC, cSt (ASTM D445) | 60.63 | |

| Viscosity Index (ASTM D2270) | 153 | |

| Viscosity @-30ºC mPa s (cP) (ASTM D5293) | 6,600 Max | 5,862 |

| Volatility, mass % loss, 1 hr, @ 250ºC (ASTM D5800) | 15 Max -c | 13.9 |

| ELEMENTAL ANALYSIS (click for test details) - a, b | ||

| Additives | ||

| Calcium, ppm | 2,045 | |

| Magnesium, ppm | 3 | |

| Phosphorus, ppm | 1,000 Max -d | 862 |

| Zinc, ppm | 954 | |

| Molybdenum, ppm | 1 | |

| Barium, ppm | <1 | |

| Boron, ppm | 12 | |

| Silicon, ppm | 2 | |

| Potassium, ppm | <5 | |

| Manganese, ppm | <1 | |

| Titanium, ppm | <1 | |

| Copper, ppm | <1 | |

| Sodium, ppm | <5 | |

| Vanadium, ppm | <1 | |

| Contaminants | ||

| Silver, ppm | <1 | |

| Aluminum, ppm | <1 | |

| Chromium, ppm | <1 | |

| Iron, ppm | 2 | |

| Nickel, ppm | <1 | |

| Lead, ppm | <1 | |

| Antimony, ppm | <1 | |

| Tin, ppm | <1 | |

|

||