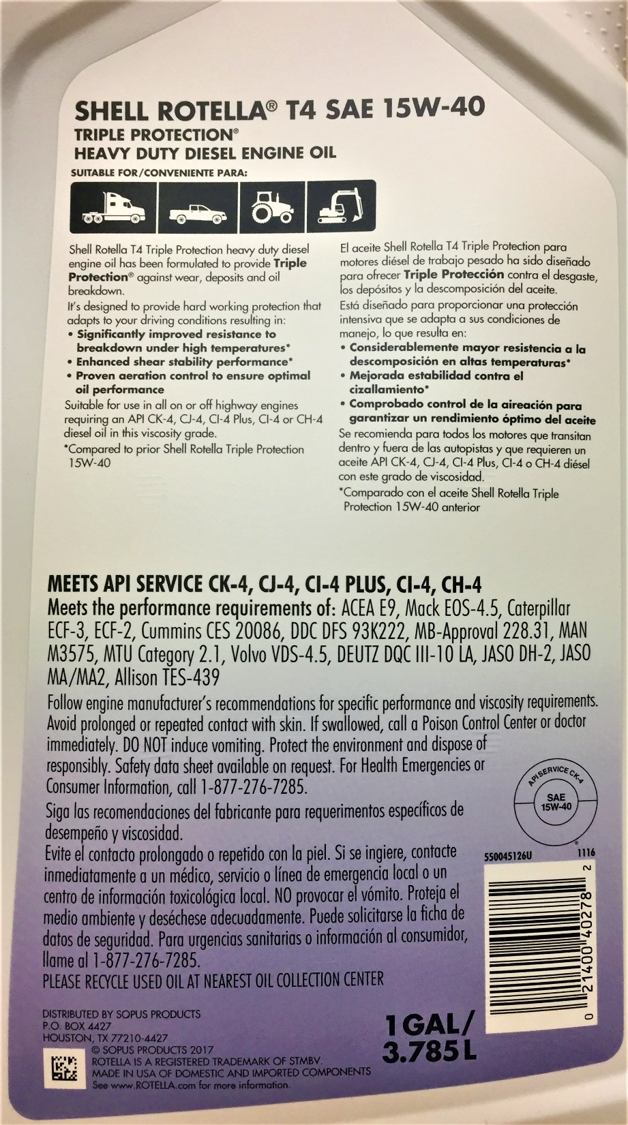

Click above for larger image

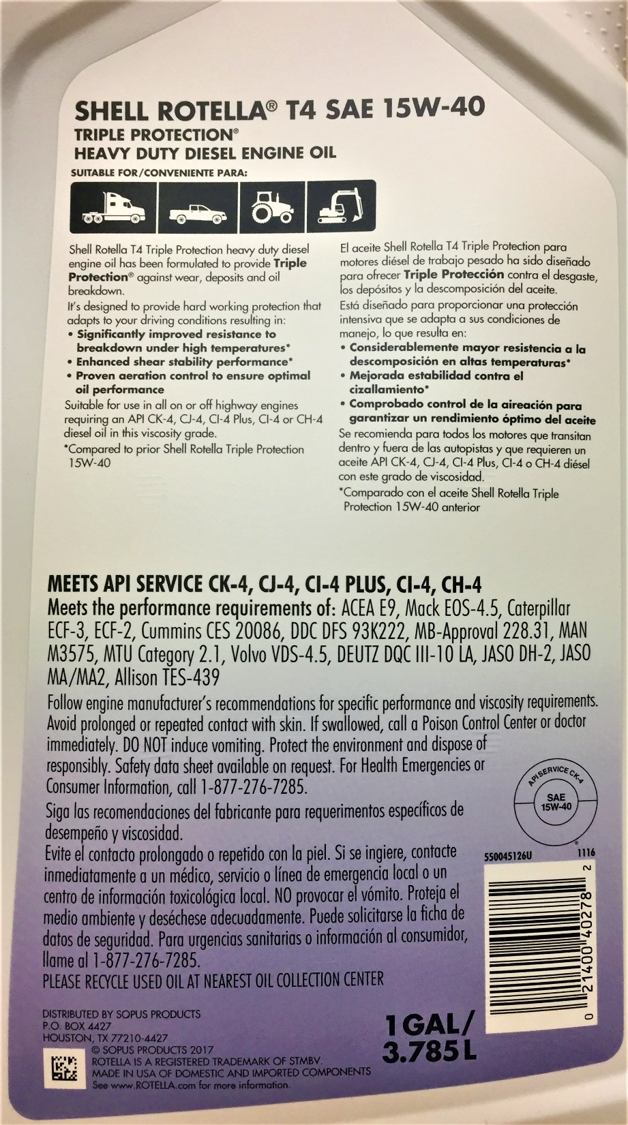

Click above for larger image

Corporate Office:

SOPUS Products

700 Milam

Houston, TX 77002

Website(s): www.ROTELLA.com

Shell Oil Company US (SOPUS) is the United States-based subsidiary of Royal Dutch Shell. Royal Dutch Shell is one of the largest major oil companies in the world SOPUS is a leading producer of oil and natural gas, gasoline, and petrochemical products in the US.

The company is also a leading manufacturer and marketer of motor oils and other automotive and industrial lubricants and products. In addition to Shell branded lubricants, Pennzoil-Quaker State Company, doing business as SOPUS Products, Inc., produces motor oils and other automotive products under the Pennzoil and Quaker State brand names.

Distributed By: SOPUS Products, Houston, TX

Purchased at: Saint Robert, MO

Date of purchase: 3/30/2017

Website(s): www.ROTELLA.com

The results of the tests conducted on this sample meet the SAE J300 specifications for the SAE Viscosity Grade listed on the product label, and are consistent with the listed API Service Categories.

|

Physical Properties |  |

||||||||

| Elemental Analysis |  |

|||||||||

| Labeling |  |

|||||||||

|

||||||||||

Note1: Although laboratory tests alone cannot be used to establish if engine oil meets an API Service Category, they can be used to determine if it doesn't. Note2: The specification for cold cranking viscosity includes only a maximum value; the minimum value shown in the “standard” area of the chart is truncated for illustrative purposes.

| PHYSICAL TESTS (click for test details) - a | Standard | Shell Rotella T4 |

| TBN, mg KOH/g (ASTM D2896) | 10.27 | |

| Viscosity @ 100ºC, cSt (ASTM D445) | 12.5 to <16.3 | 14.84 |

| Viscosity @40ºC, cSt (ASTM D445) | 113.72 | |

| Viscosity Index (ASTM D2270) | 135 | |

| Viscosity @-20ºC mPa s (cP) (ASTM D5293) | 7,000 Max | 6,010 |

| Volatility, mass % loss, 1 hr, @ 250ºC (ASTM D5800) | 13 Max -c | 11.7 |

| ELEMENTAL ANALYSIS (click for test details) - a, b | ||

| Additives | ||

| Calcium, ppm | 2,295 | |

| Magnesium, ppm | 12 | |

| Phosphorus, ppm | 1,200 Max | 1,080 |

| Zinc, ppm | 1,203 | |

| Molybdenum, ppm | <1 | |

| Barium, ppm | <1 | |

| Boron, ppm | 207 | |

| Silicon, ppm | 5 | |

| Potassium, ppm | 7 | |

| Manganese, ppm | <1 | |

| Titanium, ppm | <1 | |

| Copper, ppm | <1 | |

| Sodium, ppm | <5 | |

| Vanadium, ppm | <1 | |

| Contaminants | ||

| Silver, ppm | <1 | |

| Aluminum, ppm | <1 | |

| Chromium, ppm | <1 | |

| Iron, ppm | 1 | |

| Nickel, ppm | <1 | |

| Lead, ppm | 1 | |

| Antimony, ppm | <1 | |

| Tin, ppm | <1 | |

|

||