Product Tested

Click above for larger image

Click above for larger image

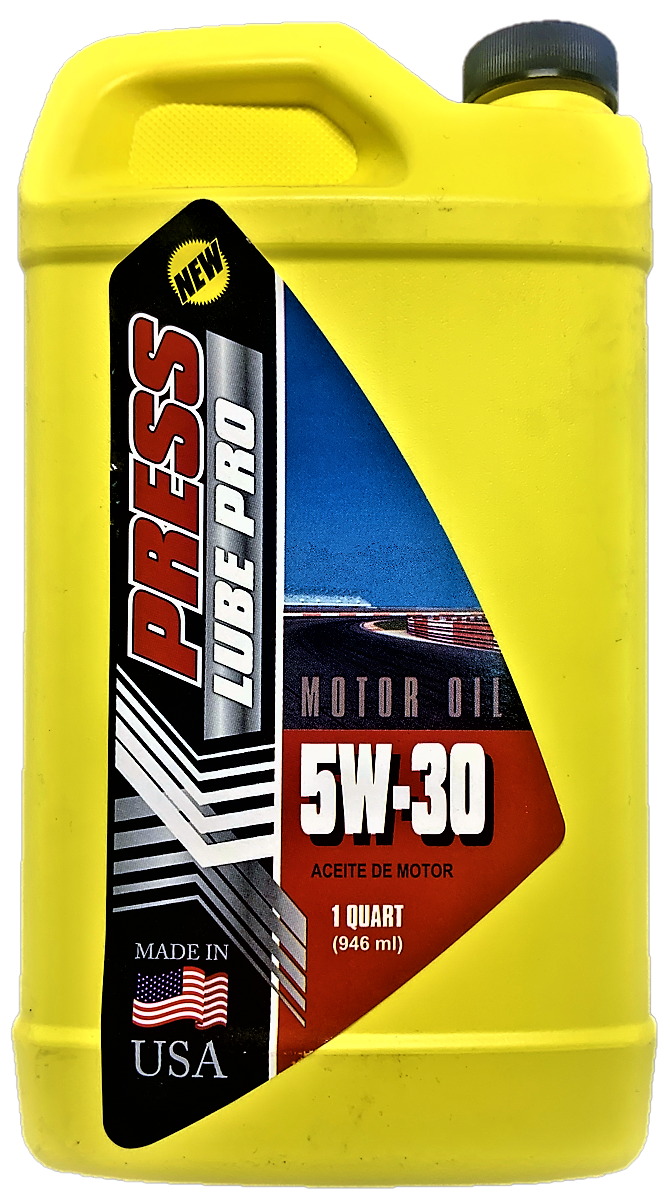

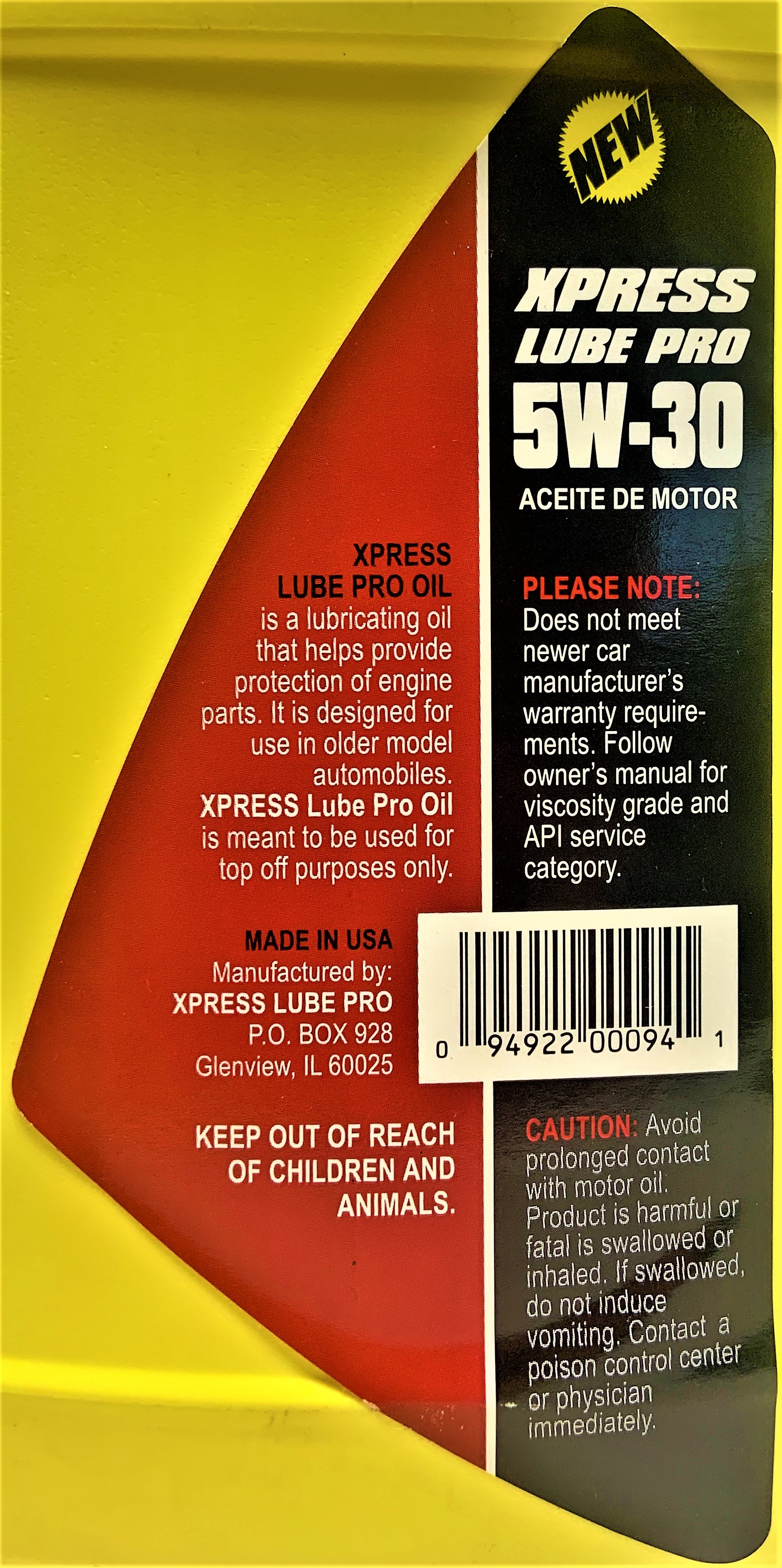

XPRESS LUBE PRO

Company and Product Information

Corporate Office:

XPRESS LUBE PRO

P.O. Box 928

Glenview, IL 60025

Website(s): No Website Found

Xpress Lube Pro

5W-30 Motor Oil

Product: XPRESS LUBE PRO

Viscosity Grade: 5W-30

Labeled: No API Listed

Manufactured By: XPRESS LUBE PRO, Glenview, IL

Purchased at: Youngstown, OH

Date of purchase: 5/14/2019

Website(s): No Website Found

Test Results and Assessment:

The results of the tests conducted on this sample do NOT meet the SAE J300 specifications for the SAE Viscosity Grade listed on the product label. The Kinematic Viscosity @ 100°C is 30% lower than the minimum viscosity specification for this SAE grade.

In addition, although the label on this product does not claim it meets any API Service Category, the test results on this sample indicates the product lacks any meaningful level of additives to protect engines from wear, sludge, and corrosion. Further, the organometallic analysis results indicate the product may contain used oil and abrasive material. For these reasons, the product is NOT suitable for use in virtually all automobile engines currently on the road.

Use of this product in virtually all automobile engines will likely cause harm to the engine.

Note: The results of the tests conducted on this sample do not meet the SAE J300 viscosity specifications for an SAE 5W-30 motor oil, the viscosity declaration on the front and back labels of this product do not conform to the SAE J300 labeling requirements and those set forth in NIST Handbook 130 which state the viscosity grade must be preceded by “SAE”.

|

Physical Properties |  |

||||

| Elemental Analysis |  |

|||||

| Labeling |  |

|||||

|

||||||

Note1: Although laboratory tests alone cannot be used to establish if engine oil meets an API Service Category, they can be used to determine if it doesn't. Note2: The specification for cold cranking viscosity includes only a maximum value; the minimum value shown in the “standard” area of the chart is truncated for illustrative purposes.

| PHYSICAL TESTS (click for test details) - a | Standard | Xpress Lube Pro |

| TBN, mg KOH/g (ASTM D2896) | ||

| Viscosity @ 100ºC, cSt (ASTM D445) | 9.3 to <12.5 | |

| Viscosity @40ºC, cSt (ASTM D445) | 32.4 | |

| Viscosity Index (ASTM D2270) | 160 | |

| Viscosity @-30ºC mPa s (cP) (ASTM D5293) | 6,600 Max | |

| ELEMENTAL ANALYSIS (click for test details) - a, b | ||

| Additives | ||

| Calcium, ppm | 94 | |

| Magnesium, ppm | 18 | |

| Phosphorus, ppm | 151 | |

| Zinc, ppm | 67 | |

| Molybdenum, ppm | 1 | |

| Barium, ppm | 12 | |

| Boron, ppm | 1 | |

| Silicon, ppm | ||

| Potassium, ppm | 1 | |

| Manganese, ppm | 1 | |

| Titanium, ppm | <1 | |

| Copper, ppm | ||

| Sodium, ppm | 2 | |

| Vanadium, ppm | <1 | |

| Contaminants | ||

| Silver, ppm | <1 | |

| Aluminum, ppm | 2 | |

| Chromium, ppm | <1 | |

| Iron, ppm | ||

| Nickel, ppm | <1 | |

| Lead, ppm | 2 | |

| Antimony, ppm | 1 | |

| Tin, ppm | <1 | |

|

||